sources of error in vickers hardness test|is 1501 pdf free download : member club The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which . webNami - One Piece by Lovebyte Labs. Welcome to Hentai Harem | NAMI Character Preview! DOGGYSTYLE UPDATE AVAILABLE NOW. Choose a position and fuck-your-favorite in .

{plog:ftitle_list}

Resultado da 12 de jul. de 2022 · Pensando nisso, o Entretê listou abaixo, 22 atrizes famosas que já estamparam as páginas da revista masculina e foram um verdadeiro sucesso de vendas na época. Nomes como o de Juliana Paes, Deborah Secco, Alessandra Negrini, Flávissa Alessandra e Danielle Winits .

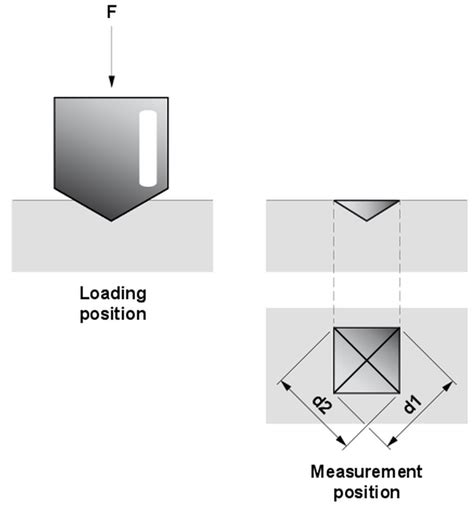

The unrivaled source of error in microhardness testing is that induced by the operator. This gets compounded when surface preparation is poor and when the “heat of the battle” is on. The mundane nature of measuring multiple impressions also contributes to fatigue and subsequent .The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which .

runnig compression test

Another common source of error is recording and converting results from microns to Vickers or Knoop hardness numbers. Measurement of 32.3μm can easily become 33.2μm. The Newage CAMS (Computer Assisted .GUIDELINES ON THE ESTIMATION OF UNCERTAINTY IN HARDNESS MEASUREMENTS. July 2007. Purpose. This document provides guidance for calibration and testing laboratories . Hardness measurements by Vickers and Brinell indentations are liable to error, even when performed by experienced operators. The authors examine the problems involved .

This work presents a theoretical evaluation of the parameters that influence the Vickers hardness (HV) error obtained by the error propagation method. Vickers indentations were .

running a compression test

Fig. 5 - Load vs. Vickers hardness test results for two testers using a quenched and tempered 440C martensitic stainless steel specimen. Tester A is red, tester B is blue. The greatest source of error is measuring the indent, as documented . Hardness measurements by Vickers and Brinell indentations are liable to error, even when performed by experienced operators. The authors examine the problems involved .Vickers test procedure. In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter is measured. In contrast, the indentation size is measured in the Brinell, Vickers and Knoop .A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide .

running a compression test on a hemi engine

Barbato and Desogus ISO 146-1984. Metallic materials - Hardness test - Verification of Vickers hardness testing machines HV O, 2 to HV 100. ISO 640-1984. Metallic materials - Hardness test - Calibration of standardized blocks to be used for Vickers hardness testing machines HV 0, 2 to HV 100. ISO/DP 4546. Verification of microhardness testing .

Mechanical Metallurgy Questions and Answers – Hardness Test – Microhardness Test ; Aerospace Materials and Processes Questions and Answers – Aircraft Materials – Hardness testing – Vickers and Shore Scleroscope Hardness ; Testing of Materials Questions and Answers – Microhardness Test ; Mechanical Metallurgy Questions and Answers .Vickers-Armstrong Ltda., the test method has become popu-lar as Vickers hardness. Vickers hardness tests can be used in many applications, as in mechanical components industry, surface treatments, glasses and laminates, being also present in laboratories and universities with applications in several kinds of materialsThe ideal d / D ratio (d = impression diameter, D = ball diameter) for a spherical indenter is 0.375. If tangents are drawn to the ball at the impression edges for d / D = 0.375, they meet below the center of the impression at an angle of 136 degrees, the angle chosen for the Vickers indenter.. Diamond allows the Vickers test to evaluate any material and, furthermore, has the very .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

The Vickers hardness test, an offshoot of the venerable Brinell test, has been used since the early 1920s. Although the concept of using one test method to cover a wide range of materials hasn’t changed much in the last 90 years, upgrades to the equipment used to perform the test have expanded its use and accuracy. The Vickers hardness number is the load (test .

EN ISO 6507-1 specifies he following are the three ranges of test force and their corresponding Vickers hardness test designations: F ≥ 49.03 N - Designation: HV 5 - Standard Vickers hardness test method for testing metals and materials with a medium to high hardness range. 1.961 ≤ F < 49.03 N - Designation: HV 0.2 to

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative . 3. Vickers Hardness (HV) Vickers hardness is determined by pressing a diamond square cone with a 136° top angle and a load of up to 120kg into the material’s surface. The Vickers hardness value (HV) is calculated by dividing the load by the surface area of the indentation pit, expressed in kgf/mm². 4. Leeb Hardness (HLD)

vickers hardness test procedure pdf

vickers hardness test manual

HV (Vickers Hardness Number) testing can be performed under loads ranging from 1 gf to 100 kgf. The versatility in load range allows it to be used for micro to macro hardness testing. Methodology. The Vickers hardness test measures material hardness by determining the size of an indentation made by a diamond pyramid-shaped indenter under a . The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.

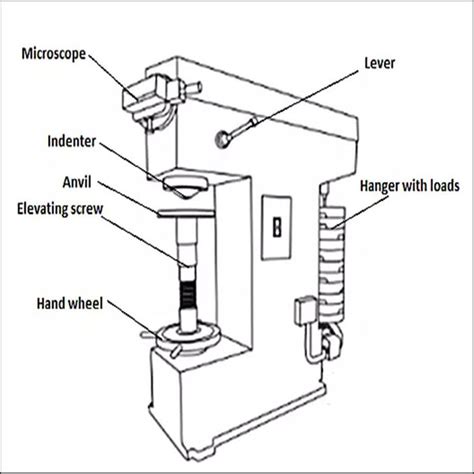

Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method .

rockwell hardness tester procedure pdf

The Vickers hardness number (HV) is calculated based on the indentation diagonal lengths. This method is suitable for a wide range of materials, including metals, ceramics, and plastics. Due to its small indentation size the Vickers hardness test allows for testing on very thin materials and provides accurate results. Where: HV is the Vickers . Effect of the variation of the mean indentation diagonal, for different values of d , on the relative uncertainty of Vickers hardness. The green, black and magenta lines represent the size of the . where α is the percentage crystallinity; H C is the hardness of fully crystalline PP, and H A is the hardness of fully amorphous PP. Using hardness testing with loads of 0.25 and 0.5 N and with a loading cycle of 0.1 min, Martinez Salazar et al. were able to extrapolate to show H C = 30 MPa and H A = 116 MPa. Whereas, this is useful information, there is ambiguity with .

perform macro Vickers hardness tests as previously defined in Test Method E92, Standard Test Method for Vickers Hardness Testing. 1.4 This test method includes an analysis of the possible sources of errors that can occur during Knoop and Vickers testing and how these factors affect the accuracy, repeatability, and reproducibility of test results.

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements. The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .

Vickers hardness testing, also called microhardness testing, is typically used for small parts, thin sections, or or case depth work. The Vickers method is based on an optical measurement system. The Microhardness testing procedure, ASTM E-384, specifies a series of light loads in which a diamond indenter makes an impression that is measured .HV = Vickers hardness When the mean diagonal of the indentation has been determined the Vickers hardness may be calculated from the formula, but is more convenient to use conversion tables. The Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was obtained using a 10 kgf force.Vickers Hardness Testing The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance:

Learn why all science experiments have error, how to calculate it, and the sources and types of errors you should report.

The objective of this paper is to analyse the influence of the specimen inclination on Vickers hardness measurements. A primary Vickers hardness testing machine (PVHM), and hardness reference test blocks with different hardness levels areBrinell hardness HBS(HBW) Vickers hardness HV Table 2 Measurements, their units and symbols Measurements Units Symbol Permanent increase in depth of penetration under preliminary test force after removal of additional force 0.002mm (regular scale) 0.001mm (superficial scale) h Single diameter of the indention mm d 1(HB), d 2(HB) By their nature, microhardness testers are delicate instruments. Extremely light forces (typically from 10 to 1,000 g.) must be accurately applied, and the resultant impressions (some as small as 10 microns) must be precisely measured under high magnification. And so there are a number of problems inherent to all of them. When people think of microhardness .

Vickers hardness testing is commonly employed as part of quality control processes in industries where material reliability and consistency are critical. Vickers hardness test can contribute to material certification, compliance with industry standards, and ensuring the integrity of manufactured products.

running compression engine test

running compression test 4.3 liter

Resultado da Get Anderson Dairy Misty Mints delivered to you in as fast as 1 .

sources of error in vickers hardness test|is 1501 pdf free download